|

|

|||

|

|

|

|

|

|

|||||||||

|

Product Catalog |

Technical Info |

About Us |

Order Direct |

Dealers |

Contact

|

|

Callaham Vintage S Model Strat Bridge Assembly Details 2006 Enhanced |

|

| Available for Purchase Here |

|

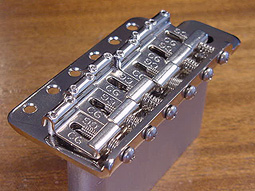

Our Vintage S Model Start bridge is considered the finest in the industry. It is the small details that make the difference. We use stainless steel screws for the intonation, saddle height, and top plate mounting screws. The 6 heat treated hardened pivot screws are essential. The top plate is cold-rolled carbon steel that is nickel plated. And in 2006 we incorporated our enhanced vintage tremolo block and our "64" Virtual Pop-in stainless steel arm design (block details).

|

|

.jpg) Callaham Vintage S Model Bridge Assembly

Callaham Vintage S Model Bridge Assembly

|

Close up of

Close up of Callaham Vintage "CG" saddles, top plate, and tremolo block |

Improvements: |

||

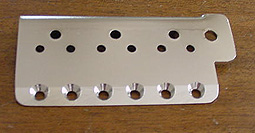

Callaham Vintage S Model

Callaham Vintage S ModelTop Plate |

Current Fender production and

Current Fender production and Custom Shop Top Plate |

|

The bevel on the bottom side of the plate - which allows the bridge to pivot - must not extend past the diameter of the pivot screw. We take care in machining this angle, which allows the bridge to pivot along a single axis. |

||

|

||

| Callaham * | Pre-CBS | Current production |

|

Our saddles are designed off of original Pre-CBS saddles, but with several improvements. The above picture shows a Callaham, a Pre-CBS, and a current production Fender® saddle. We have slightly lengthened the string slot compared to the Pre-CBS saddle so that the string will not bind and bend against the sharp edge before it goes over the saddle. This greatly reduces string breakage and improves intonation. As you can see, the current production saddle's string slot is moved too far to the rear. This causes string breakage and loss of downward pressure on the saddle - hurting both sustain and tone. |

|

||

| Callaham * | Pre-CBS | Current production |

|

The above picture shows the threads of both the Callaham and the Pre-CBS saddles running the entire length of the front edge. The current production saddle only has a few threads and has a much shorter front edge. It is extremely important that the height screws are held securely with as much thread contact as possible to maintain sustain and saddle stability. There is the belief that the Pre-CBS saddles were "hardened". Every Pre-CBS saddle we have tested, only measures an average of 50 Rockwell B and were not hardened. We choose to use a steel with a hardness of 95-98 Rockwell B for our saddles. The steel work hardens in the making of the saddle and is well over 115 Rockwell B where the string crosses. |

||

|

Installation: On vintage styled bridges the pivot screws need to be down almost to the top plate. I screw the screw down until it touches the plate and lifts the back off the body. Then back the screw off until the plate rests back down on the body. You should feel small movements, side to side and forward and back of the bridge. It pivots fully up and down. Too far down and the bridge will bind. Too far away and the bridge will slide up the screws. Both mistakes cause tuning problems. I recommend a minimum of 4 springs for the bridges. They should be set so that if you are doing double stop bends, the guitar remains at pitch. This means the top plate will have a slight pressure against the body. Sorry no pull ups with a vintage bridge, unless you can live with pitch problems. |

||

* old pictures of Callaham saddle without "CG" stamping. |

||

| For Ordering Instructions and Shipping Rates, go to our Order Direct page. | |

| Prices and Content subject to change without notice. |

| © 1996-2016 by Callaham Guitars™. All rights reserved. This website is protected by copyright and trademark laws under U.S. and International law. All images and content may not be reproduced without written permission of Callaham Guitars™. Stratocaster®, Strat® & Tele® are registered trademarks of Fender Musical Instruments Corp. Callaham Guitars™ is not affiliated with Fender Musical Instruments Corp. This page last modified August 23, 2016 |

| Callaham Guitars ™ |

|

Home |

Product Catalog |

Technical Info |

About Us |

Contact

Order Direct | Printable Order Form | Dealers Strat® Parts | Tele® Parts | Gibson® Parts | Bigsby® Parts |